We listen to you, understand your processes, and work together to develop customized solutions that are precisely tailored to your requirements.

Rely on the original in the direct imaging market and benefit from DART—our new patented real-time rasterization technology that captures hundreds of measurement points per second, automatically compensates for distortions, and significantly reduces your reject rate.

In high-tech manufacturing, the adaptability of your systems is often the deciding factor between success and downtime. We know the typical stumbling blocks - from excessive rejects and long set-up times to inflexible systems.

This is exactly where MIVA comes in: Discover how we can optimize your production processes with custom-fit, modular direct imaging solutions and personal service tailored to your needs.

Although today's technology is very precise, a certain amount of rejects of up to 4% still occur in production.

Experience has shown that our technology reduces this waste by a further 25% while maintaining the same high product quality.

Slow alignment, time-consuming mask changes and long set-up times slow down your throughput.

Our LED direct imagers with DART Scan achieve 4× faster registration and up to 15,000 light pulses/s.

Top machines are expensive to purchase and maintain - ROI often takes years.

MIVA systems pay for themselves more quickly: lower operating costs, predictable service contracts and higher yields ensure a significantly shorter pay-back phase.

Standard machines often require upgrading or conversion when you switch from prototypes to series or other formats - this costs time, money and slows down your production.

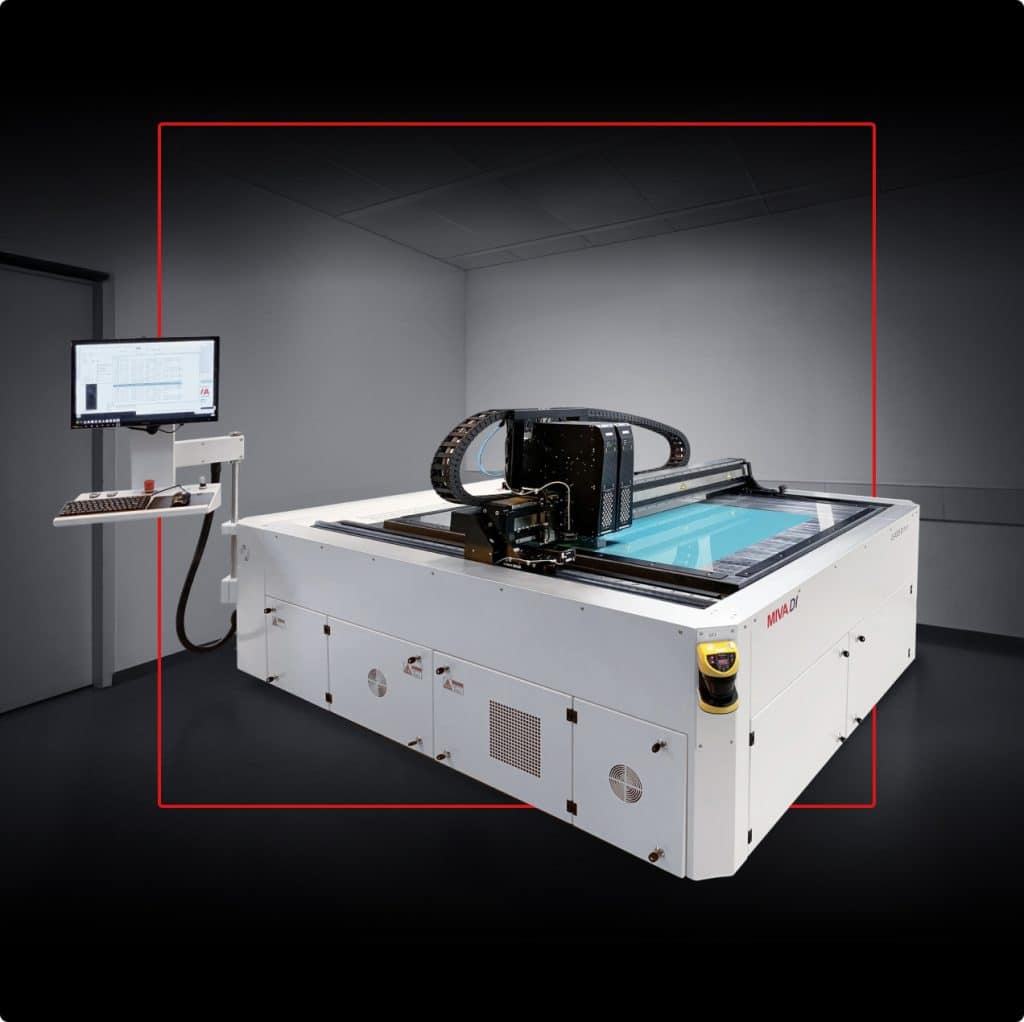

With MIVA, you can realize prototypes and series production on the same modular system. Our customized systems adapt to your processes - whether panel size 30″×60″ or roll-to-roll, from small series to mass production.

Downtime, expensive spare parts and long service intervals block your capacities.

Thanks to the granite base, fewer moving components and personal support within 24 hours, MIVA systems run like Swiss clockwork.

Off-the-shelf machines don't understand your processes - and anonymous hotlines don't solve your problems.

We listen, understand your processes and develop customized systems that really fit. With our personal support (remote & on-site), there are no long downtimes, but genuine co-engineering solutions.

Whether you are looking for a proven standard machine in the field of direct imaging, want to adjust fine details, or need a direct imager that is fully tailored to your process, MIVA is the right choice for you.

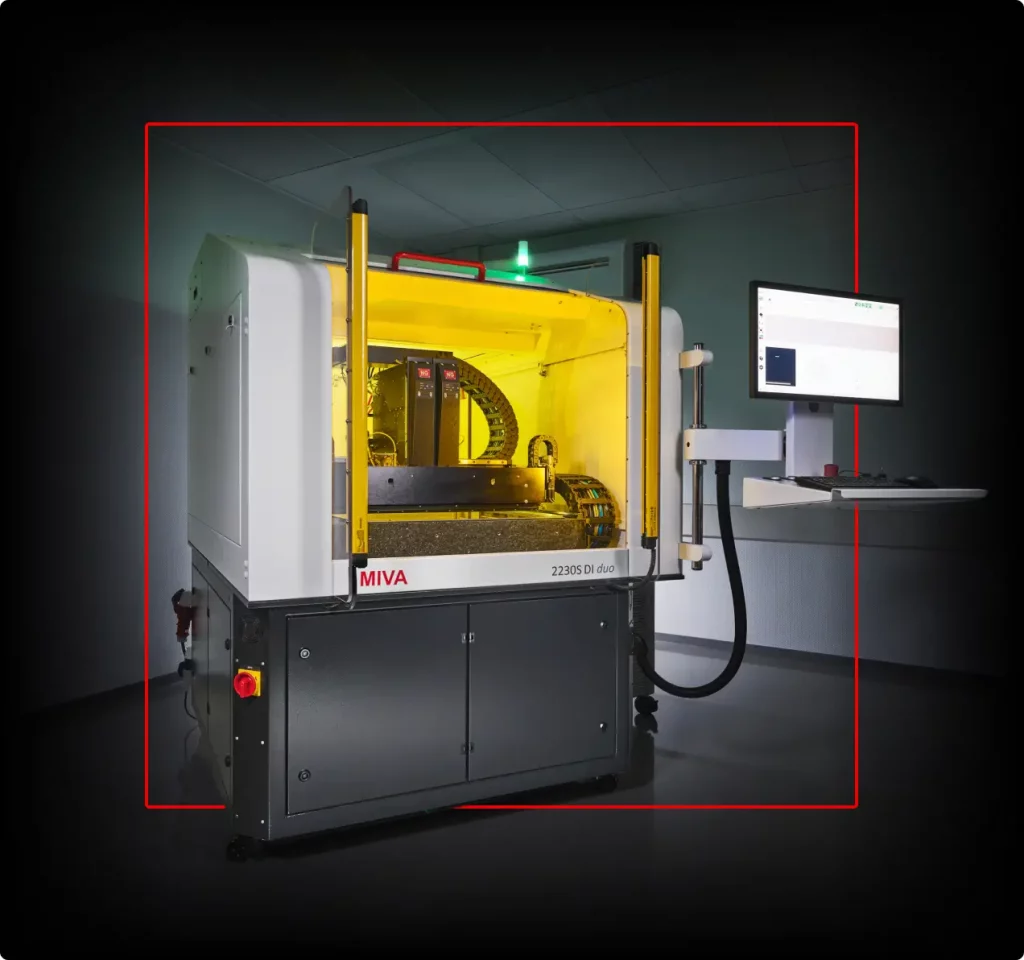

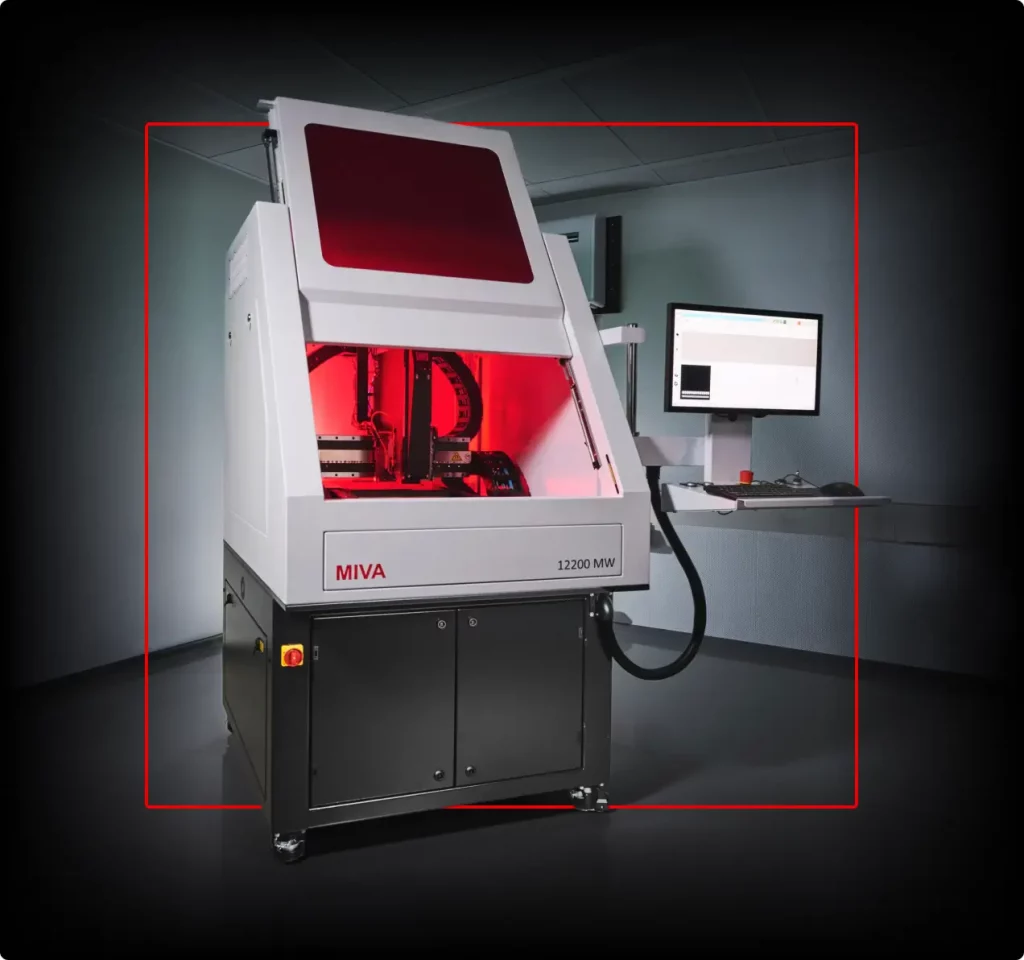

Get to know our three standard machines (direct imaging and mask writing) as a solid foundation that we can customize to your requirements. With our modular, tailor-made approach, we plan and implement systems that...

and always accompanied by our personal support within 24 hours.

Our patented real-time rasterization combines software and hardware in four modules:

Uses the built-in machine camera to measure line widths and feature sizes directly after exposure and readjust them digitally in real time.

Creates a complete 3D height profile of your exposed surface after developing/etching and thus uncovers printing or etching deviations.

Scans hundreds to thousands of measuring points over the entire panel surface in 1-3 seconds (instead of 2-4 points in 8-10 seconds).

Automatically adjusts drill holes and laser cuts to the measured actual scale ("best fit") instead of working rigidly according to target data.

Click here for more projects

Swipe to continue reading

US-American date tool does not match DE format, manual reworking of each component necessary.

Software change in the mask file: Calendar format dynamically selectable.

100% error-free traceability, no more manual corrections, time saving per batch: in this case up to 2 hours.

Pump noise and heat development were disturbing in the room where the machine is located.

Pump relocated to adjacent plant room via extension cable.

Less noise and a more stable room temperature for more comfortable working conditions. No additional cooling required.

Standard exposure in the focus point not suitable for uneven substrates.

Adjustment of the autofocus algorithm and exposure offsets for multi-Z profile.

Uniform exposure across all elevations, yield increase of 20.5%, fewer rejects for MEMS components.

Swipe to continue reading

Tiny marking for traceability currently only possible on big plates, but not on small plates.

Development of a sub-mask layout that exposes large and small areas simultaneously, including inline verification.

Seamless direct printing of QR codes on large and small boards - 100% traceability, >99% scanning success and up to 2h time saving per batch.

Single-panel exposure too slow for series SMD processes, high personnel input.

Integration of an inline roller drive (R2R) plus control logic for continuous exposure in endless production.

Throughput increased by 150 % (instead of 100 panels/h now 250 panels/h), personnel costs halved, seamless entry into series production.

Customer occasionally needs 2 µm resolution for detail islands, otherwise 30 µm standard is sufficient.

Dual exposure mode implemented: fast coarse exposure + fine high-res exposure in a single operation.

Savings on a second system (approx. 300k €.Overall process 40 % faster, full process flexibility without setup changes.

Flexible printed circuit boards for the automotive industry were to be exposed continuously up to 15 m in length, while standard machines only processed 600 mm segments.

Integration of an R2R indexing module that guides the substrate through the exposure unit in 1-2 s steps with positional accuracy.

15 m exposure in one run without interruption, 70 % less post-processing due to elimination of segment seams, 40 % shorter production time, flawless, seamless patterns for curved LED strips and in-car displays.

Since 1986, we have been combining in-depth engineering expertise with genuine partnership. Our founder, Robin Pagan, helped develop the exposure head technologies that set the standard throughout the industry today. This pioneering work—from early raster photoplotters to modern direct imaging systems—gave rise to a clear philosophy: innovative technology follows the process, not the other way around.

Because our partners' everyday work is not rigid: materials vary, designs change, cycle times increase. Our response to this is machines that adapt to your process, not the other way around – through modular architecture, customized configurations, and DART, our digital adaptive rasterization in real time. This results in solutions that are precise, scalable, and economical in the long term. In short: MIVA – meet(s) your needs.

The focus is on your success throughout the entire life cycle—not just a one-time purchase. What sets MIVA apart is our cooperation and the handshake you can rely on: we listen, think ahead in your processes, and deliver on time—from the first meeting to the production line. This gives you a partnership on equal terms with tailor-made solutions and reliable service that ensures quality, precision, speed, and cost-effectiveness in the long term.

Benzstraße 17, 71101 Schönaich

+49 (0) 7031 75600

info@mivatec.com

Swipe to continue reading

Select a suitable date for you in our online appointment calendar. A personal meeting is the best way to identify your wishes.

Let us know the area of application, formats/materials, desired resolution and timing - optionally attach important files that will give us a better insight in preparation for the joint appointment.

We will check your documents and discuss all further details during the appointment. On this basis, we will then draw up a customized offer for you.

Still unsure or have a quick question? We will be happy to call you back.

The quickest way is to make an appointment in the calendar. If you don't want to commit yet or have a quick question in advance, leave your number here. We will contact you as soon as possible for a short, free preliminary discussion.

Duration: approx. 5–10 minutes

Depending on the application, typically significantly faster due to higher yield, less set-up time and predictable services. On request, we can provide an ROI estimate based on your data.

Both: standard as a basis—and, if desired, detailed adjustments up to completely customized for your process. Together with you, we will find the perfect solution in the field of direct imaging or mask writing, tailored to your processes!

Response ≤ 24 h within business hours, much remotely. On site if necessary. Training & follow-up included. Our maintenance contracts start at €8,000 per year.

Yes, our systems scale from prototype to series production without changing platforms. This gives you maximum flexibility now and for tomorrow.

Compared to other providers on the market, our machines are very compact, around 30% smaller. In addition, we check your environment in advance and make the necessary and possible adjustments so that it is right for you.

Once you have decided on a MIVA machine, we will deliver it on time in approx. 2-4 months - depending on the specific requirements and scope, of course, but usually much sooner. Our record: 10 days after ordering or sometimes 3.5 weeks after ordering.

Approximately one week after commissioning, one of our technicians will visit you in person to check and ensure that everything is in order. If you have any further questions, we are always available for you, even remotely.

Can be read directly into the machine:

Available via a converter:

Other formats available on request.

MES/ERP connection available e.g. via OPC UA and Modbus. Other protocols or connections on request

In your production, the first exposure step determines everything that follows: Quality, cycle, deadlines, trust. We are convinced that technology must serve the process - every day, under real conditions. That's why we take responsibility right where precision begins.

We listen, map your process and work with you to develop a configuration that fits today and grows with you tomorrow.

Our DART technology thinks in real time, compensates for deviations before they become expensive, and our compact granite systems (direct imagesetters and mask writers) deliver stable repeat accuracy, high yield and fast changeovers. Options only come along for the ride if they bring real benefits.

And if things get stuck, talk to people, not ticket numbers - to someone who knows your system, has seen your drawings and understands your goals. Short lines of communication, quick feedback - we stay on it until it's up and running and even after that. That's the handshake you can count on and the partnership you can build on.

Take the next step: find your customized direct imaging solution. Our entire team is already looking forward to getting to know you and helping you to make your imaging more precise, faster and more economical!

Best regards,

Inventor + Founder / Managing Director

It is best to enter your cell phone number so that we can reach you quickly. Alternatively, you can also provide your email address as an additional contact option.

After clicking on the button to execute the service, your data will be usedand processed in accordance with our privacy policy. At the same time, you authorize MIVA Technologies GmbH to pass on your data to all companies and cooperation partners necessary for the process in order to execute the service.