MIVA is a pioneer in direct imaging & mask writing: standard as a basis, customized details and tailor-made when it counts.

More output with the same machine, up to 25% less waste and faster approvals - accompanied by a partner whose support you can rely on.

Choose your basis - and expand it so that it perfectly supports and ideally optimizes your process.

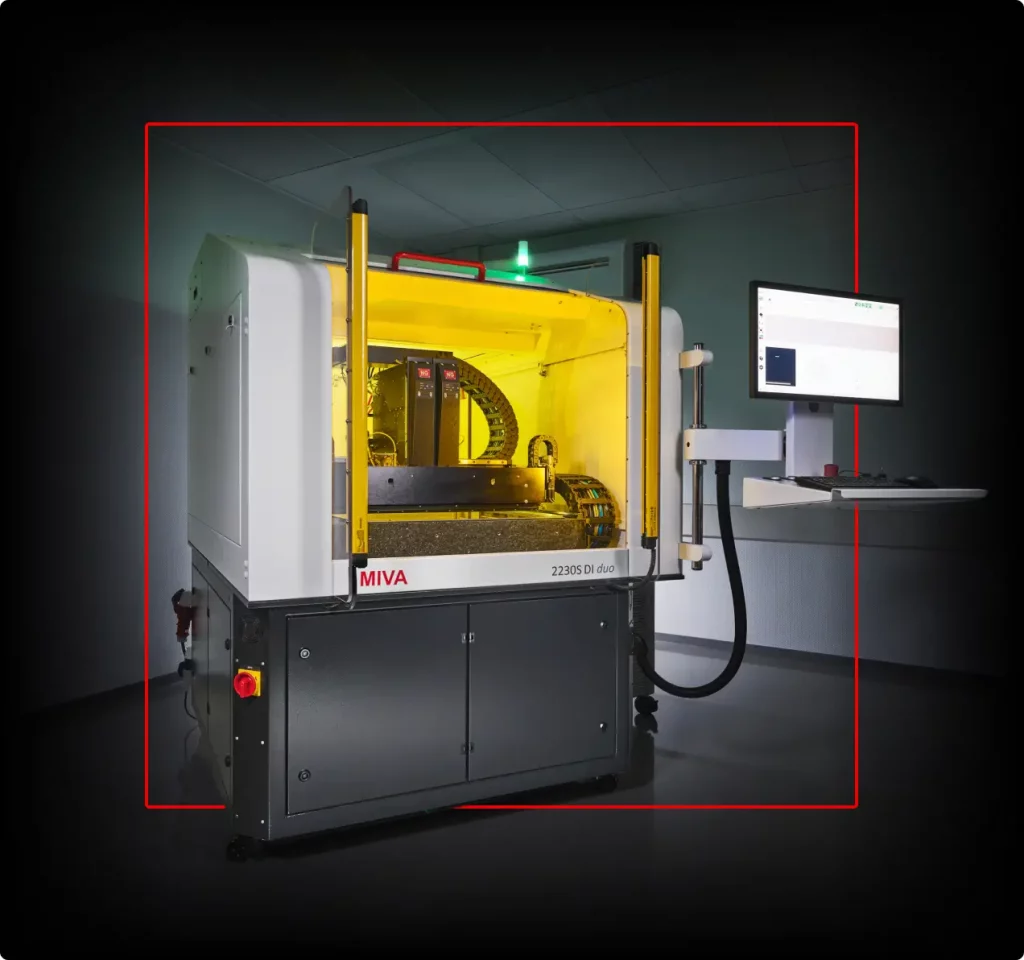

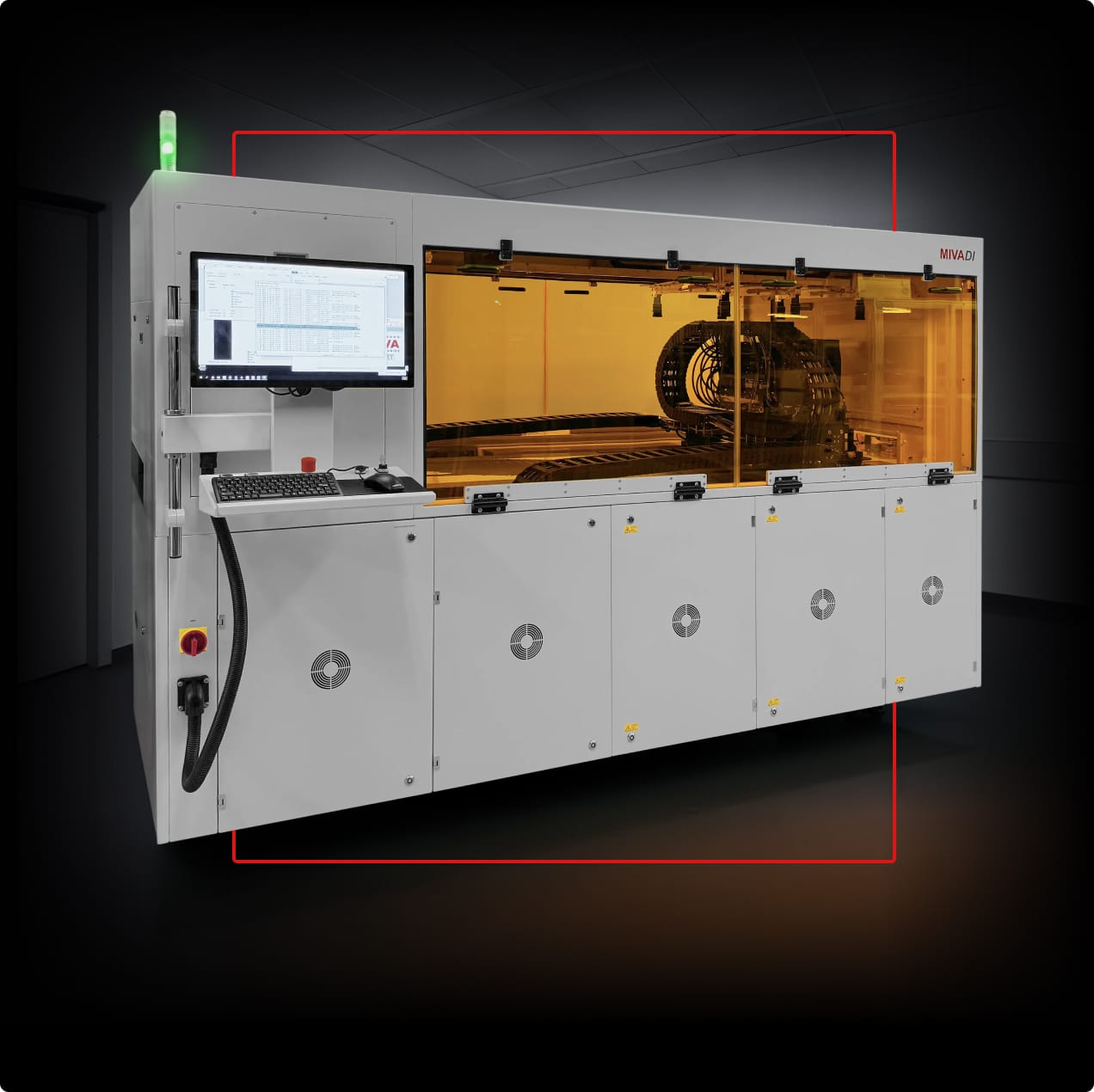

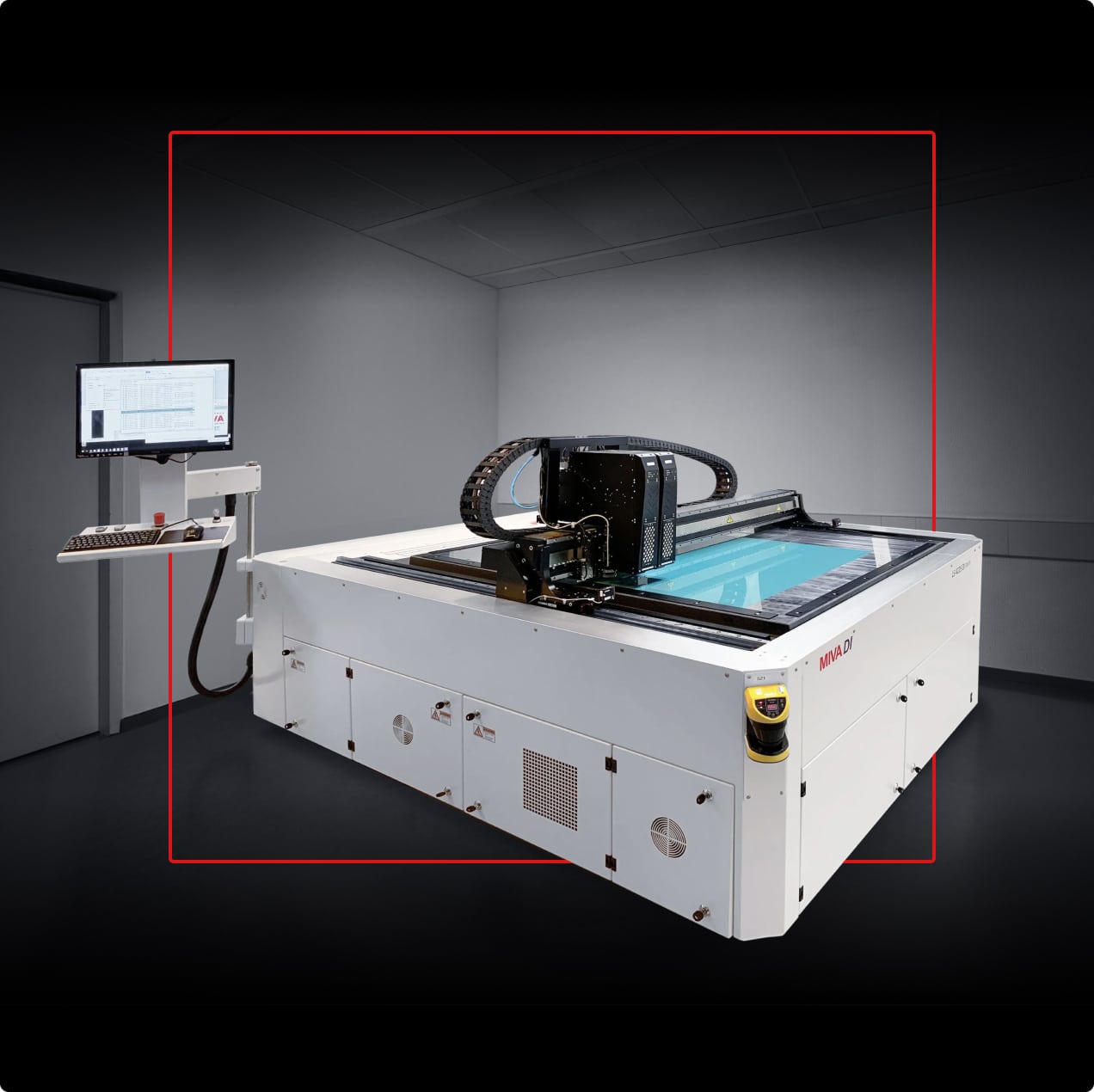

Our three basic machines form the foundation - the rest is up to you.

From additional photo heads, wavelengths and optics to special formats, R2R/overlengths with indexing, multi-resolution setups and our DART modules: We configure and expand so that the machine follows your process - not the other way around.

On request, we can adapt software presets to your materials, for example, or realize details with a big effect (e.g. QR codes on "little plates", date formats, low-noise peripheral placement).

Our approach is co-engineering: We take time for your environment, analyse target variables (yield, cycle, formats, materials), check sample data, define acceptance criteria and develop your overall concept from this.

All with one goal: more output with the same machine, less waste, reliable deadlines - efficient today, scalable tomorrow.

Contact us - we will show you in a free process consultation which configuration suits your goals and what hidden potential lies in your line.

What if your first pass was right every time?

DART closes the exposure loop: scan full area, correct on the fly, expose verified - for ~4× faster alignment, up to 2,000 targets per 5sec and ~25% better registration.

In short: precision that thinks for itself.

The panel is captured in its entirety, the exposure is adjusted with pixel precision in real time and the result is verified immediately. This results in consistent quality, higher yield, fewer rejects and faster approvals - from prototype to series production.

DART sets new standards - the standard of tomorrow in process control.

Measures line widths/features after exposure and digitally adjusts to target.

Creates a 3D topography image after developing/etching; shows print/etch variations.

Up to 2,000 measuring points in 4s - instead of a few measuring points in 8-12s

Separate scaling for laser and mechanical drilling; tracks follow an optimized weighting

*Note: DART Drill is configured independently of DART Scan (compatibility per machine/project - we will be happy to advise you).

Click on the respective box for more information

At MIVA, our service does not end with the handover of the machine. We see service as a partnership: listening, thinking and delivering - from the first conversation to stable everyday production and beyond. And we do this without any constraints, but with transparent and fair calculations, always with the aim of keeping your production line reliable so that your deadlines and costs can be planned.

What you can expect from us in concrete terms:

Swipe to compare

Performance

Bronze

silver

Gold

Technical hotline support- unlimited access by phone, e-mail, TeamViewer

Replacement of all filters according to maintenance schedule - HEPA, cooling water, compressed air

Remote support - online diagnostics & online configuration support

Preventive maintenance - inspection & calibration according to recommended intervals

Software upgrades - provision of new versions of licensed MIVA software

Prioritized service & support - guaranteed, faster response times

Extended warranty - full coverage incl. parts and service costs

We see service as a partnership - and we want to prove to you that our promises are kept in everyday life.

Many of our customers have entered into long-term cooperation with us from the very first project for precisely this reason: because reliability, short distances and a fair framework are what counts.

With MIVA, you benefit in two ways: from a machine that adapts to your process and from a service that proactively supports you afterwards - with clear response times, remote solutions and predictable packages (bronze, silver, gold), without unnecessary contractual obligations.

Let's talk without obligation: In 45 minutes, we will clarify your goals, operational environment and support requirements - if you wish, we can start lean and scale up as your needs grow. This is how you get to know us and our handshake approach: listen, think, deliver.

Select a suitable date for you in our online appointment calendar. A personal meeting is the best way to identify your wishes.

Let us know the area of application, formats/materials, desired resolution and timing - optionally attach important files that will give us a better insight in preparation for the joint appointment.

We will check your documents and discuss all further details during the appointment. On this basis, we will then draw up a customized offer for you.

MIVA uses CRT technology for photoplotters

First MIVA photoplotter presentation

MIVA now uses LCD modules for the photoplotters

First vertical photoplotter with a granite base for greater accuracy

Development of direct imagesetters with DMD technology

Delivery of the first direct exposure unit with dual wave multi-light engine in Germany

First delivery to a customer in Vietnam

First quad-wave DI application delivered

First direct exposure unit with a 1.5-micron photo head for very small structures

First large format machine with 42 "x 60" to a defense company in the US

First machine with NextGeneration photo heads

Development and delivery of a machine with DART Scan

+ The birth of our new MIVA falcon

Depending on the application, typically significantly faster due to higher yield, less set-up time and predictable services. On request, we can provide an ROI estimate based on your data.

Yes - one platform for both, and without changing platforms.

DART is available platform-wide; the modules can be configured according to requirements.

Yes - Automation-Ready, Indexing and R2R are possible (3000L Custom).

Quad-Wave LED covers common resist/solder masks; formats from 24″×30″ to 42″×60″ (and more than custom).

Gerber and TIFF can be read in directly. Other formats can be integrated via a converter, e.g. OASIS, ODB++, GDS, DXF, CIF, PostScript/EPS and many more on request.

Yes, we can exchange data with MES/ERP systems via OPC UA or Modbus. Other protocols or connections can be implemented.

Yes, we always do that. You are welcome to use an initial online meeting to get to know us.

This depends very much on your project. A standard machine can start production in just a few weeks.

Yes - we are represented in North America and also in Asia.

Yes - we offer various maintenance contracts as standard. These can also be customized according to individual requirements.

≤ 24-hour response within business hours, much remotely and on-site if required, plus training/follow-ups.

It is best to enter your cell phone number so that we can reach you quickly. Alternatively, you can also provide your email address as an additional contact option.

After clicking on the button to execute the service, your data will be usedand processed in accordance with our privacy policy. At the same time, you authorize MIVA Technologies GmbH to pass on your data to all companies and cooperation partners necessary for the process in order to execute the service.